Things to consider before buying the best Resin 3D Printer

Published On: 2023-03-08

Resin 3D printing refers to a class of additive manufacturing technologies that cure liquid photopolymers into solid objects layer by layer. It is not an official name for the entire group, but it is a more simple way of describing them all together. Stereolithography and VAT polymerization printing are two examples.

What is polymerization?

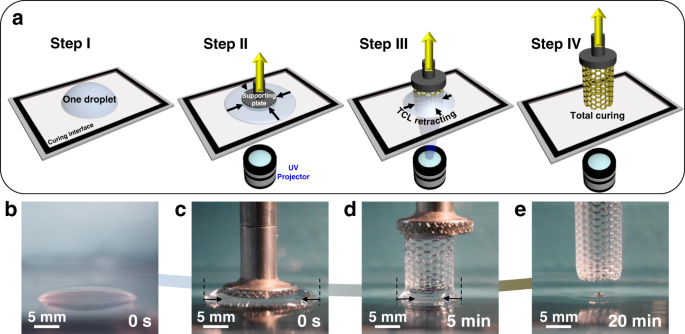

When a liquid material is exposed to light, a chemical reaction called photopolymerization occurs. Photopolymers or light-activated resins are technical terms, but in 3D printing, they are simply referred to as resins. The photopolymerization procedures and outputs differ, but the basic step is solidifying in the presence of the appropriate wave light. The technical kind is determined by various light sources.

Common resin printing process

The resin tank is filled with resin material either manually or mechanically. Because certain resins are harmful, an expert should avoid direct contact with the resin.

The build platform is lowered (or raised) by the machine to deposit a thin coating of resin on the build plate.

A light source causes the resin to solidify by creating a pattern in it.

The platform shifts in order to allow uncured (liquid) resin to pass through and establish a new thin layer above the plate.

If a unit has a roller, it will go around the building to make sure the resin is properly put.

The procedure is repeated till the finished product is created. Upon the completion of the procedure, the object is removed from the machine for further processing.

Washing – Uncured resin remains must be removed from a print. To achieve this, prints are put in alcohol, water, or simply let to dry on paper towels.

Curing – Prints are strengthened and solidified by exposing them to sunshine or a UV-lamp. Because each layer is only exposed to light for a few seconds when printing, post-curing is required.

Supports Removal – This entails removing all of the supporting structures of an object. To maintain an object and attach it to a construction plate during resin printing, many tree-like supports are required. These supports are frequently simple to remove, but it can be a time-consuming task that requires caution to prevent considerably reducing the volume of the item.

In addition to the post-processing processes listed above, resin prints could also be treated with the below mentioned processes for further detailing or strength. The procedures outlined below can be completed manually or with the assistance of specialized devices and technology. Semi-automated desktop units to entire industrial complexes are available for washing, drying, and sanding.

Sanding – this is used to smooth or matte the surface and remove taps from areas where supports have touched an object. It can be accomplished using either dry or wet sanding equipment. The latter involves the application of specialist solutions, polishers, or just adding water to conventional sanding papers. Wet sanding can make a print’s surface smoother.

Patching escape holes – Patching is a post-processing procedure that allows resin to escape from the interior of hollow objects. It entails physically filling these gaps with resin or other materials to improve the structure and appearance.

Finishing – this is the process of reinforcing and hiding flaws in things by coating them with certain compositions or coatings. Priming, on the other hand, is the process of preparing a surface for painting. To minimise overcuring and degradation under UV light, many resins require a coating.

Painting – these come in a variety of colours and compositions.

Polishing – this is a process that uses chemicals to make the surface even clearer and smoother, particularly after sanding. This stage is critical for obtaining a clear outcome.

What material is used for resin 3D printing?

Resin 3D printing refers to 3D printers that use resin-cured liquid photopolymers (resins). These resins differ due to the presence of monomers, oligomers, and photoinitiators in the blend. As a result, they differ in:

Wavelength of the light that is required for curing;

Solidification exposure time;

Stiffness and strength;

The highest resolution possible;

Biocompatibility;

Resistant to chemicals and mechanical forces.

Common UV resin types

Standard Resin: It is a versatile photopolymer that may be used in a variety of applications. Printed objects with ordinary resin are robust and strong, having a rubbery feel. Translucent orangyorange resin is the most basic of common resins since it is the most sensitive to UV radiation.

Glass-reinforced resin: glass additives are used in polymers to increase strength and stiffness, making them more resistant to distortion and abrasion.

When compared to non-photopolymers, the material intended for use in components subjected to mechanical stress and wear has some elasticity, comparable to Polypropylene.

Flexible Resin: The substance solidifies to a “rubber-like” consistency, providing elasticity and flexibility for flexible prototypes.

Tough resin—an ABS-like material—is used for strong parts and prototypes that will not deform when stressed. Prints are less elastic than resin prints, yet they keep their structure well.

Dental Resin: Some photopolymers are biocompatible and can be used in the medical industry for end-use products and equipment, providing wear resistance and accuracy.

High-temperature resin: Developed for prototypes and parts that may be exposed to high temperatures, prints can withstand temperatures up to 536 degrees Fahrenheit.

Castable Resin: Moldmakers and jewelers use this resin line to generate master models for investment casting, resulting in no ash and clean burnouts.

Shell Casting Resin: This resin is used to make soft pieces in shell casting; the print is a mold by itself, thus reducing process time and costs

Advantages of Resin Printing summarised –

Excellent attention to detail; because photopolymers are injected into a printer as a liquid, they are easier to mold into complex forms than melted plastics.

Layer lines are still present in resin printing; however, they are thin and practically imperceptible on some resin colors.

The resin industry satisfies all typical uses and demands, and the list is expanding all the time. Each photopolymer resin comprises both reaction components as well as additives such as colors and other visual and functional additives.

The surface is not significantly harmed by the supports. Because the resin tank is totally full, any lightweight overhangs may be easily attached to the main body of a part during curing.

Extremely quick. Resin printing is significantly faster than other prototyping methods, and newer machines can print at breakneck speeds.

Resin printing reduces expenses for various applications, such as prototypes, dental equipment, and jewelry master models. And photopolymers are solid and waterproof, making them suitable for water-tight applications.

Disadvantages of Resin Printing summarised –

Experts recommend arranging an item in such a way that it does not contact the plate and “fly” at a 45-degree angle to create solid supporting structures that cannot be recycled.

Large goods are expensive to produce due to the need for expensive photopolymer for large prints and industrial equipment, increasing work costs.

Resin printing has a set of requirements that must be met before a project can be completed, such as engraved details being at least 0.4 mm wide and thick, component orientations and mesh quality, and skill and experience.

Post-processing is necessary to prepare pieces for usage, and post-curing is essential to prevent shrinkage, cracks, and deformation after polymerization.

Expensive machines: Prices for SLA and industrial-grade machinery range from $3,500–$4,000 to $250,000 per unit.

Types of resin printing

SLA

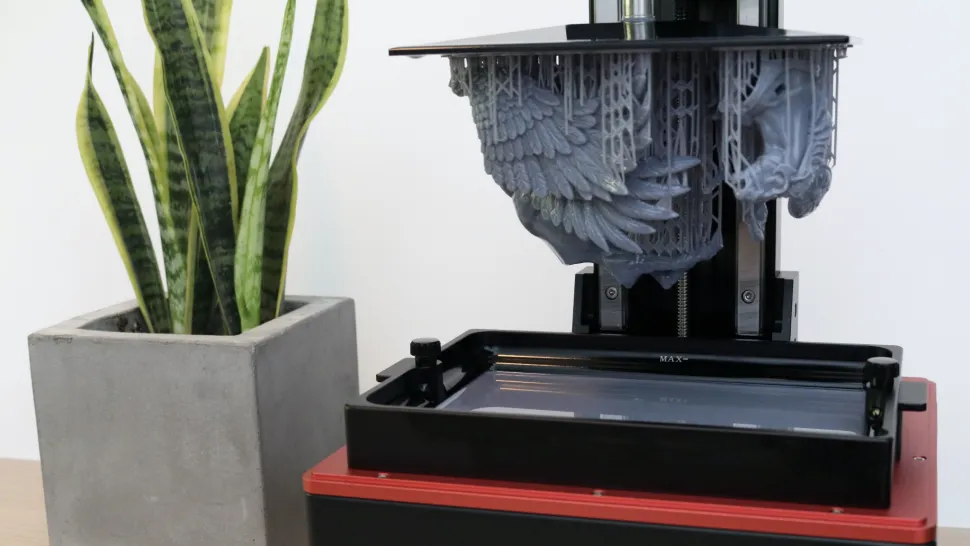

SLA machines manufacture items differently than FDM (FFF) 3D printers, using a liquid resin component that hardens when exposed to UV light instead of plastic. Resin printing requires support structures to allow formed items to attach to the generated plate and hang “in the air” at a 45-degree angle for improved quality. Finished models must be post-cured to complete the resin printing process.

MSLA

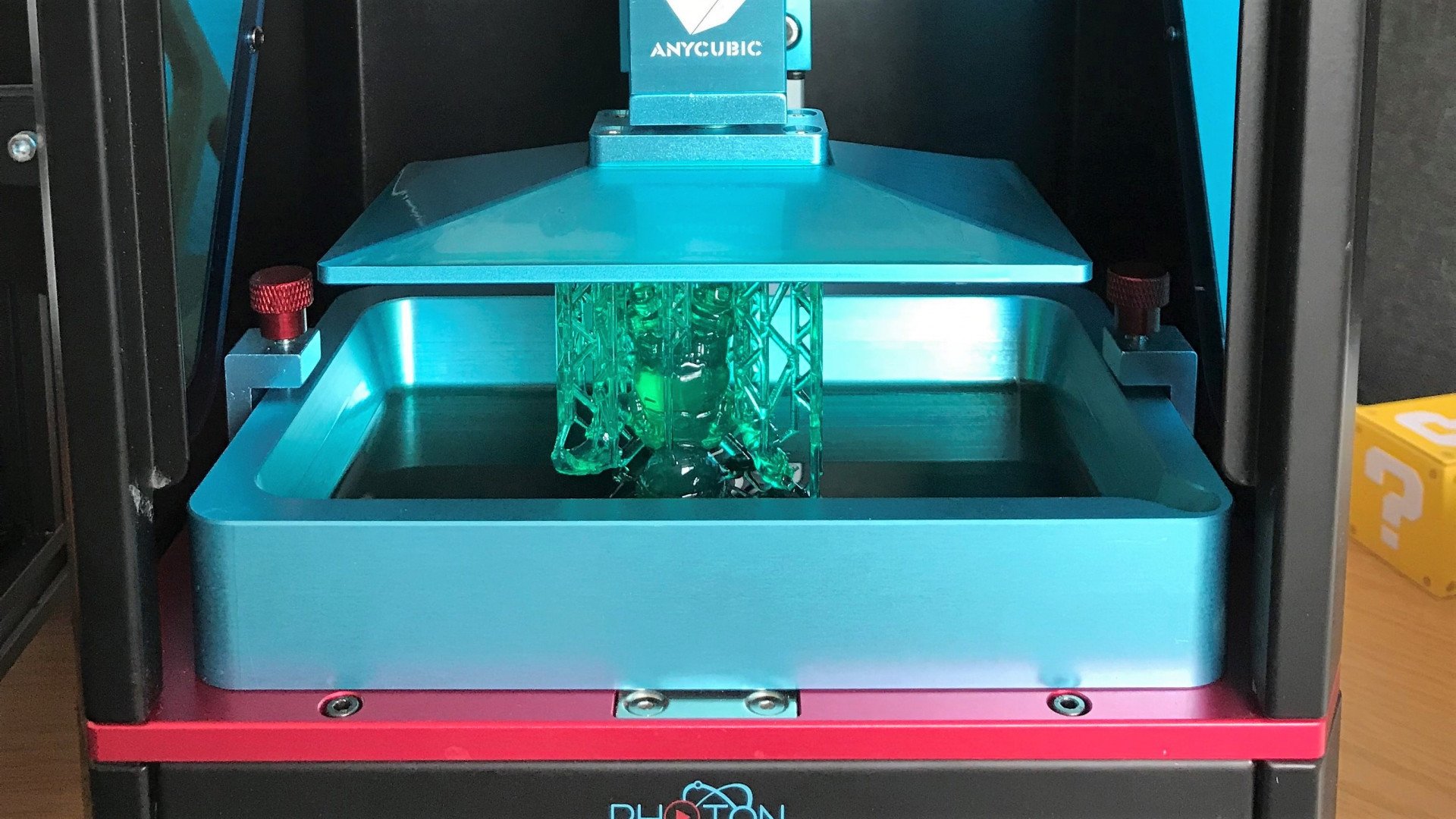

MSLA (masked stereolithography equipment) is an improved version of SLA (stereolithography) 3D printing that combines an LCD screen with a strong LED light source to selectively cure photosensitive resin and create a three-dimensional object. The light source is projected via an LCD screen that serves as a mask.

MSLA 3D printing has several advantages, such as producing high-quality items in large quantities at a low cost and being quicker and more precise than conventional 3D printing procedures. However, the expense of the printers and the need for extreme caution make it difficult for many organisations to afford. The MSLA 3D printer is made up of a resin tank, a digital mask, a light array, and a build platform. This article will explain how it works and discuss the materials utilised.

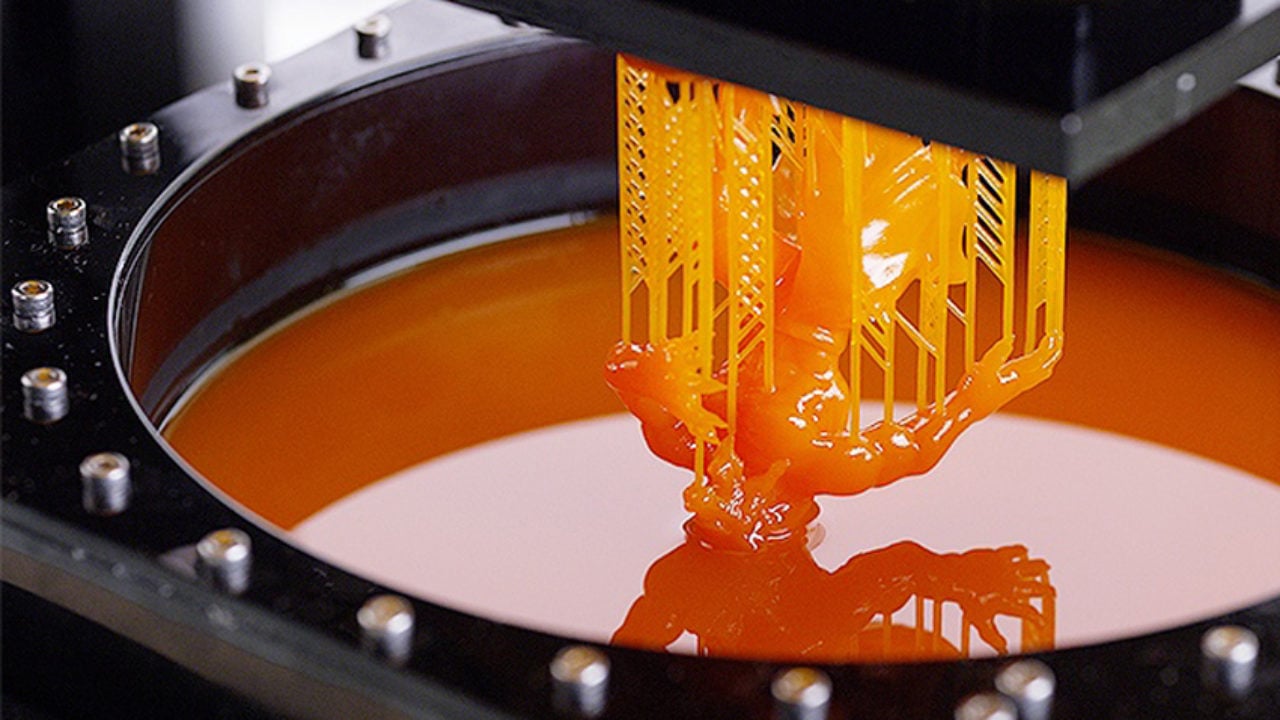

DLP

Digital Light Processing technology is quite similar to SLA where the fundamental distinction between these two procedures is the light source used to cure UV resin. DLP printers employ projectors, while others use flat LCD panels. As a result, LCD devices, as opposed to DLP, are less prone to pixel distortion concerns.

While these DLP printers print the models a lot quicker than SLA printers and prints the object sin square pixels. But, you should be aware that LCD printers range in terms of LCD density, which has a direct impact on the printing resolution you may expect. Some models appear to be low-cost, however, this might suggest that inferior materials and panels were used to compete in the low-cost market.

Both DLP and SLA 3D printers can create precise features and smooth surfaces, but SLA is commonly cited as a more exact technique due to its circle laser beam. The most common complaint is that items are built with square pixels, but projector-based machines are getting better with high-resolution light sources, enhancing the capabilities of DLP 3D printers in terms of precision and smoothness.

When compared to FDM, DLP technology has the upper hand in giving better details, smoothness, and geometric freedom. Along with these, it is easier to remove the supports on the prints from DLP machines.

DLP and LCD panel resolutions refer to the number of lines and pixels that may be shown on a single screen or projection. There were two options: 720p (HD ready) or 1080p (full HD). The Asiga Max, Atum3D DLP Station 5, Miicraft Hyper series, and 3DSystems all employ a full HD (1080P; 1920 x 1080 pixel) DLP module. Several older DLP printer models, as well as the recently introduced Anycubic Photon Ultra, use 720P DLP.

Therefore, the better the resolution of the screen, the better the quality of the print. Along with the quality of the print, the price of the printer would be higher as well.